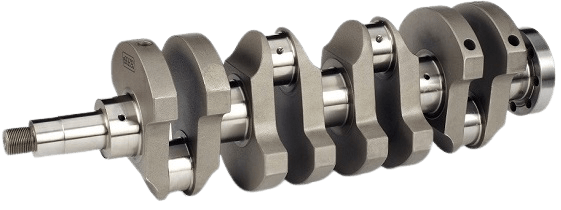

BMW Crank

The crank is a part that converts the energy obtained from the movement of the pistons in internal combustion engines into rotational motion by transmitting it to the engine.

BMW Crankshaft: Features and Historical Development

The BMW crank shaft is a critical component located at the heart of internal combustion engines, converting the linear motion of the pistons into rotational motion. BMW engines use sophisticated crankshafts designed to offer high performance and durability. In this article, we will examine what the BMW crankshaft is, its features, and its historical development.

Features of the BMW Crankshaft

BMW crankshafts are designed and manufactured to provide high performance and long life. Here are some key features of BMW crankshafts:

High Strength and Durability: Crankshafts are made from high-strength steel alloys. This ensures that the engine can withstand high RPM and torque for extended periods.

Balanced Design: The balance of the crankshaft is critical for the smooth and vibration-free operation of the engine. BMW produces crankshafts using precise balancing techniques.

Heat Treatment: Crankshafts undergo heat treatment to enhance surface hardness and overall durability. This increases wear and fatigue resistance.

Lubrication Channels: Crankshafts have integrated lubrication channels to ensure proper lubrication of bearings and other moving parts. This reduces friction and extends the life of the components.

Precision Craftsmanship: BMW crankshafts are machined with an accuracy of one-thousandth of a millimeter. This helps ensure perfect fit and performance of the components.

Historical Development

The historical development of BMW crankshafts has continuously undergone innovations and improvements with advancements in automotive engineering and manufacturing technologies. Here are some key points regarding the historical development of crankshafts:

Early Periods (1900s): The crankshafts used in early engines were generally made of cast iron and had a simple design. These shafts operated at low RPM and power levels.

Mid Period (1950s-1970s): During this period, increases in engine performance required the use of stronger and lighter materials. The use of steel alloys became widespread, and manufacturing processes became more precise.

Modern Period (1980s-Present): Today, BMW crankshafts are produced using advanced engineering techniques and high-quality materials. Computer-aided design (CAD) and manufacturing (CAM) technologies allow for more precise and efficient production of crankshafts.

High-Performance Applications (2000s and Beyond): In modern high-performance BMW engines, crankshafts are made from high-tech materials such as titanium and other advanced alloys. Additionally, composite materials like carbon fiber are also used.

Conclusion

BMW crankshafts are critical components located at the heart of the engine, providing high performance and durability. Historically, crankshafts have continuously undergone innovations and improvements, ensuring that BMW engines deliver superior performance. Produced with high-quality materials and advanced manufacturing techniques, BMW crankshafts ensure the smooth and long-lasting operation of the engine. The historical development of crankshafts reflects advancements in automotive engineering, making each new generation of BMW engines more efficient and durable.

Türkçe

Türkçe

English

English

Русский

Русский