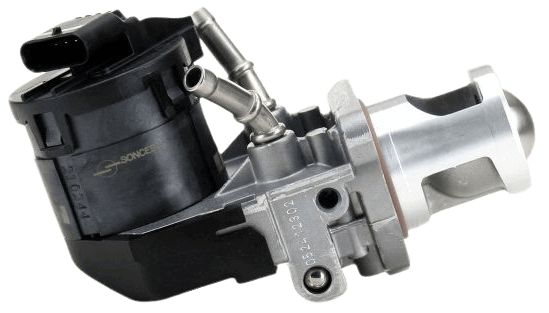

BMW EGR Valve

The BMW EGR Valve is a component that allows the cooling of exhaust gases in vehicles, thereby reducing harmful gases produced.

BMW EGR Valve: Features and Historical Development

The EGR (Exhaust Gas Recirculation) valve is an important component used in modern internal combustion engines to reduce emissions and increase engine efficiency. The EGR valve, commonly used in BMW vehicles, redirects a portion of the exhaust gases back into the combustion chamber to reduce harmful emissions. In this article, we will examine what the BMW EGR valve is, its features, and its historical development.

Features of the EGR Valve

BMW EGR valve has various features designed to control the engine's emissions and improve fuel efficiency. Here are some key features of the BMW EGR valve:

Emission Reduction: The EGR valve reduces NOx (nitrogen oxide) emissions by redirecting a portion of the exhaust gases back into the combustion chamber. This provides a more environmentally friendly and cleaner engine operation.

Fuel Efficiency: The recirculated exhaust gases lower the combustion temperature, resulting in more efficient combustion. This reduces fuel consumption and increases engine efficiency.

Heat Control: The EGR valve prevents the engine from overheating by controlling combustion temperatures. This contributes to the longevity of the engine.

Electronic Control: Modern BMW EGR valves are electronically controlled by the engine control unit (ECU). This ensures precise and rapid operation of the valve.

Durable Materials: EGR valves are made from materials that can withstand high temperatures and pressures. This ensures the valve operates smoothly for a long time.

Historical Development

The historical development of BMW EGR valves has undergone continuous innovations and improvements alongside advancements in automotive technologies. Here are some key points regarding the historical development of EGR valves:

1970s and Earlier: The first EGR valves were introduced in the 1970s in response to the need to reduce emissions. These valves were mechanically controlled and had a simple structure.

1980s: EGR systems became more common and sophisticated. During this period, vacuum-controlled EGR valves were introduced to provide more precise control.

1990s: EGR valves integrated with electronic control units (ECU) were introduced. These valves helped further reduce emissions by operating more precisely and effectively.

2000s and Beyond: In modern BMW vehicles, EGR valves are equipped with advanced technologies. Electronically controlled EGR valves provide more precise control and lower emission levels. Additionally, more durable and long-lasting materials are used.

Conclusion

The BMW EGR valve is a critical component for reducing engine emissions and improving fuel efficiency. Historically, EGR valves have undergone continuous innovations and improvements, ensuring that BMW engines operate cleaner and more efficiently. Manufactured with high-quality materials and advanced production techniques, BMW EGR valves offer both an environmentally friendly and performance-oriented driving experience. The historical development of EGR valves reflects advancements in automotive technologies, ensuring that each new generation of BMW engines is more efficient and durable.

Türkçe

Türkçe

English

English

Русский

Русский