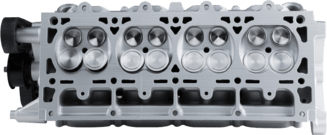

BMW Cylinder Head

BMW Cylinder head serves to cover the top of the cylinders, create combustion chambers, and provide a base for some external parts. Valves are located on the upper part of the cylinder head. These valves perform intake and exhaust functions. The upper part of the cylinders BMW Cylinder Head; is a part of the engine that covers the engine block from above, and this covering process is ensured by the cylinder head gasket.

BMW Cylinder Head: Features and Historical Development

The cylinder head is one of the critical components of internal combustion engines. The cylinder head, which covers the upper part of the combustion chamber, regulates the combustion process, facilitates the installation of valves and spark plugs, and supports the engine's cooling system. The cylinder heads used in BMW vehicles are designed to offer high performance and durability. In this article, we will examine what a BMW cylinder head is, its features, and its historical development.

Features of the Cylinder Head

BMW cylinder heads are specially designed and manufactured to ensure the efficient operation and longevity of the engine. Here are some key features of BMW cylinder heads:

1. High Strength: BMW cylinder heads are made from high-strength aluminum or steel alloys. These materials are resistant to high temperatures and pressures.

2. Advanced Technology: BMW cylinder heads are produced using advanced engineering techniques and precise manufacturing processes. This ensures high performance and reliability.

3. Heat Management: Cylinder heads effectively manage the engine's heat and support the efficient operation of the cooling system. This prevents the engine from overheating.

4. Valve and Spark Plug Installation: BMW cylinder heads facilitate the installation of valves and spark plugs, contributing to the efficient operation of the combustion chamber.

5. Sealing: Cylinder heads maintain the pressure inside the engine and prevent leaks. This enhances the engine's performance and efficiency.

Historical Development

The historical development of BMW cylinder heads has continuously undergone innovations and improvements with advancements in automotive engineering. Here are some key points regarding the historical development of cylinder heads:

1. Early Periods (1900s): The cylinder heads used in early engines were generally made of cast iron. While these materials were durable, they were heavy and inadequate in heat management.

2. Middle Period (1950s-1970s): During this period, the use of aluminum alloys became widespread. Aluminum, being lightweight and having high thermal conductivity, improved engine performance.

3. Modern Period (1980s-Present): Today, BMW cylinder heads are produced using advanced engineering techniques and high-quality materials. Computer-aided design (CAD) and manufacturing (CAM) technologies allow for more precise and efficient production of cylinder heads.

4. High-Performance Applications (2000s and Beyond): In modern high-performance BMW engines, cylinder heads have even more advanced features. Innovative materials and manufacturing techniques enable cylinder heads to offer higher performance and durability.

Conclusion

BMW cylinder heads are critical components that ensure the efficient and durable operation of the engine. Historically, cylinder heads have continuously undergone innovations and improvements, which ensures that BMW engines deliver superior performance. Manufactured with high-quality materials and advanced production techniques, BMW cylinder heads ensure the smooth and long-lasting operation of the engine. The historical development of cylinder heads reflects advancements in automotive engineering, making each new generation of BMW engines more efficient and durable.

Türkçe

Türkçe

English

English

Русский

Русский