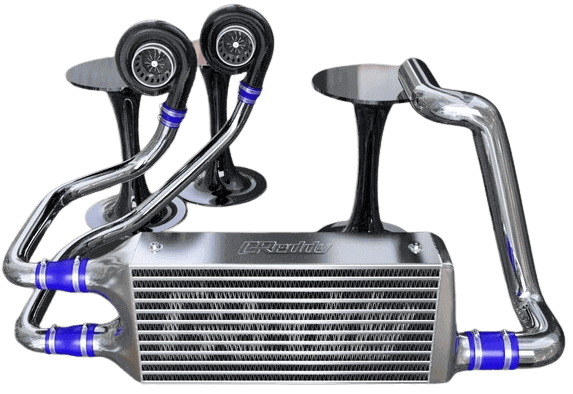

BMW intercooler

BMW intercooler; It is an external cooler used to cool the air heated by the high compression of the turbo in turbocharged engines.

BMW Intercooler: Features and Historical Development

The intercooler is an important component used to reduce the temperature of compressed air in turbocharged and supercharged engines. The intercoolers used in BMW cars are designed to enhance engine performance and efficiency. In this article, we will examine what a BMW intercooler is, its features, and its historical development.

Features of the Intercooler

The intercooler provides a denser and oxygen-rich air mixture by lowering the temperature of the compressed air. This allows the engine to operate more efficiently and achieve higher performance. Here are some key features of the BMW intercooler:

High Heat Transfer: BMW intercoolers have high heat transfer efficiency. This quickly lowers the temperature of the compressed air and allows the engine to be fed with cooler air.

Low Pressure Loss: A well-designed intercooler provides low pressure loss. This helps the turbocharger operate more efficiently and the engine produce more power.

Durability: BMW intercoolers are made from high-quality materials and are designed to withstand harsh conditions. This ensures long life and reliable performance.

Optimized Airflow: BMW intercoolers are designed to optimize airflow. This allows the engine to operate at maximum efficiency.

Performance Increase: The intercooler provides an increase in power and torque by allowing the engine to be fed with cooler air. This is a significant advantage, especially in high-performance BMW models.

Historical Development

The historical development of BMW intercoolers has continuously undergone innovations and improvements alongside advancements in automotive technologies. Here are some key points regarding the historical development of intercoolers:

First Intercoolers (1970s): The first intercoolers began to be used in turbocharged engines. During this period, basic air-to-air intercooler systems were common.

Advanced Designs (1980s): In the 1980s, intercooler designs began to evolve. Larger and more efficient intercoolers were used, and air-to-water intercooler systems were developed.

High-Performance Applications (1990s): In the 1990s, the use of intercoolers increased in high-performance BMW models. During this period, performance-oriented designs and materials began to be used.

Modern Intercooler Systems (2000s and Beyond): Since the 2000s, BMW's intercooler technology has further advanced. Features such as adaptive and intelligent systems, optimized airflow, and higher heat transfer efficiency have been added.

Conclusion

The BMW intercooler is a critical component used to reduce the temperature of compressed air in turbocharged and supercharged engines. The historical development of intercoolers has continuously undergone innovations and improvements alongside advancements in automotive technologies. Produced with high-quality materials and advanced manufacturing techniques, BMW intercoolers enhance engine performance and efficiency, providing an exceptional driving experience. The historical development of intercoolers has contributed to making BMW engines more effective and durable, allowing each new generation of BMW vehicles to offer higher performance and efficiency.

Türkçe

Türkçe

English

English

Русский

Русский