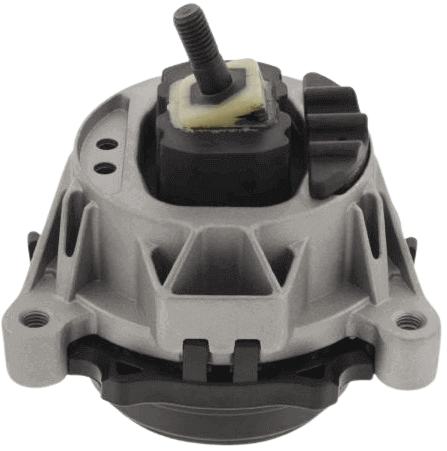

BMW Engine Mount

The BMW engine mount is a part located at the bottom of the engine that serves an absorbing function on the vibrations caused by the engine and provides balance against vehicle swaying.

BMW Engine Mount: Features and Historical Development

The BMW engine mount is an important component that ensures the engine is fixed to the chassis in internal combustion engines and absorbs the engine's vibrations to enhance the vehicle's comfort. The engine mounts used in BMW vehicles are designed to provide high performance and durability. In this article, we will examine what the BMW engine mount is, its features, and its historical development.

Features of the Engine Mount

BMW engine mounts are developed to absorb the engine's vibrations, enhancing driving comfort and ensuring the engine remains in the correct position. Here are some key features of BMW engine mounts:

Vibration Absorption: Engine mounts prevent the vibrations generated during engine operation from being transmitted to the vehicle body. This increases driving comfort and allows passengers to experience a more comfortable ride.

High Strength and Durability: BMW engine mounts are made from high-strength materials. This ensures that the engine remains stable even under heavy loads and high RPMs.

Flexibility: Engine mounts provide a certain degree of flexibility, allowing the engine to move. This allows the engine to move slightly without damaging the chassis.

Heat Resistance: BMW engine mounts are designed to withstand high temperatures. These parts, exposed to the engine's heat, are produced to be long-lasting.

Sound Isolation: Engine mounts reduce the transmission of sound generated during engine operation into the vehicle interior. This provides a quieter driving experience inside the cabin.

Historical Development

The historical development of BMW engine mounts has continuously undergone innovations and improvements with advancements in automotive technologies. Here are some key points regarding the historical development of engine mounts:

Early Periods (1900s): The first engine mounts were designed as simple rubber blocks that secured the engine to the chassis. These parts did not absorb engine vibrations sufficiently.

Middle Period (1950s-1970s): During this period, engine mounts made from more advanced rubber and metal components began to be used. These parts absorbed engine vibrations better and were more durable.

Modern Period (1980s-Present): Today, BMW engine mounts are produced using high-tech materials and advanced manufacturing techniques. Innovative solutions such as hydraulic engine mounts and active engine mounts minimize engine vibrations and noise.

High-Performance Applications (2000s and Beyond): In modern high-performance BMW vehicles, engine mounts have even more advanced features. Adaptive engine mounts optimize the engine's movement and vibrations according to driving conditions.

Conclusion

BMW engine mounts are critical components that enhance driving comfort by absorbing engine vibrations and ensuring the engine remains in the correct position. Historically, engine mounts have continuously undergone innovations and improvements, ensuring that BMW vehicles offer superior performance and comfort. Produced with high-quality materials and advanced manufacturing techniques, BMW engine mounts provide an excellent experience in terms of both durability and driving pleasure. The historical development of engine mounts reflects advancements in automotive technologies, making each new generation of BMW vehicles more efficient and comfortable.

Türkçe

Türkçe

English

English

Русский

Русский