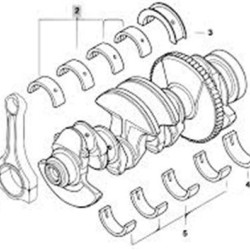

BMW Connecting Rod Bearing

BMW Connecting Rod Bearing; is the name given to the engine parts placed between the crankshaft and the wider part of the connecting rod.

BMW Connecting Rod Bearings: Features and Historical Development

Connecting rod bearings are an important component of internal combustion engines. They provide the connection between the connecting rod and the crankshaft, ensuring the engine operates smoothly and efficiently. The connecting rod bearings used in BMW vehicles are designed to offer high performance and durability. In this article, we will examine what BMW connecting rod bearings are, their features, and their historical development.

Features of Connecting Rod Bearings

Connecting rod bearings operate under extreme pressure and temperature conditions within the engine. Therefore, they need to be made from high-quality materials and designed with tight tolerances. Here are some key features of BMW connecting rod bearings:

High Strength and Durability: BMW connecting rod bearings are made from high-strength alloys. This ensures that the bearings are long-lasting even under high pressure and temperature.

Low Friction: By using high-quality bearing materials and precision surface processing techniques, low friction and wear are achieved. This contributes to the efficient operation of the engine.

Heat Distribution: BMW connecting rod bearings ensure even heat distribution. This helps the engine run cooler and reduces the risk of overheating.

Precise Tolerances: Precision manufacturing processes allow connecting rod bearings to be produced with tight tolerances. This helps the bearings fit perfectly within the engine and minimizes vibration.

Easy Maintenance and Replacement: BMW connecting rod bearings are designed for ease of maintenance and replacement. This makes engine repairs faster and more efficient.

Historical Development

The historical development of connecting rod bearings has progressed in parallel with technological advancements in the automotive industry. Here are some key points regarding the historical development of connecting rod bearings:

Early Period (1900s): The connecting rod bearings used in the first internal combustion engines were typically made of bronze or brass. These bearings operated under low speed and pressure.

Middle Period (1950s-1970s): With the development of higher performance engines, steel and other high-strength alloys began to be used in connecting rod bearings. During this period, more precise tolerances were applied in the production of bearings.

Modern Period (1980s-Present): Today, BMW connecting rod bearings are produced using the latest technology. Advanced materials science and manufacturing techniques ensure that the bearings have higher strength, durability, and low friction properties. Additionally, modern manufacturing processes allow bearings to be produced with tighter tolerances and at lower costs.

Conclusion

BMW connecting rod bearings are a critical component that ensures the efficient and durable operation of the engine. With features such as high strength, low friction, and precise tolerances, BMW connecting rod bearings enhance engine performance and longevity. Continuously improved and developed throughout their historical evolution, connecting rod bearings have contributed to providing higher performance and durability in BMW engines. Thanks to advancements in today's technology and materials science, BMW connecting rod bearings continue to set the standards of excellence in the automotive industry.

Türkçe

Türkçe

English

English

Русский

Русский