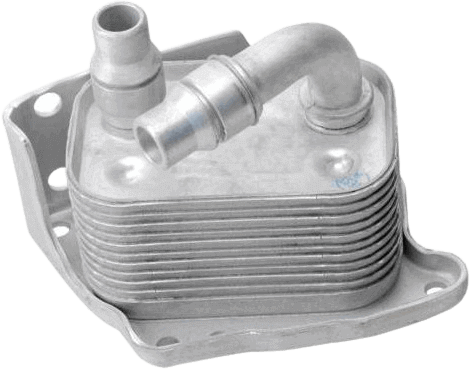

BMW Oil Cooler

BMW Oil cooler; They are cooling radiators used to cool the oils of engines that operate for long periods at very low or high revolutions.

BMW Oil Cooler: Features and Historical Development

The oil cooler is a component used to reduce the temperature of engine oil in internal combustion engines and ensure the efficient operation of the engine. Engine oil heats up as it is distributed to different areas of the engine, and removing this heat is critical to prevent the engine from overheating. The oil coolers used in BMW vehicles are designed to offer high performance and durability. In this article, we will examine what a BMW oil cooler is, its features, and its historical development.

Features of the Oil Cooler

BMW oil coolers are specially designed and manufactured to ensure the efficient operation and longevity of the engine. Here are some key features of BMW oil coolers:

1. High Heat Transfer Capacity: BMW oil coolers have a high heat transfer capacity to quickly and effectively reduce the temperature of engine oil.

2. Durability and Reliability: BMW oil coolers are made from high-quality materials. This ensures that the oil coolers are long-lasting and provide reliable performance even under challenging working conditions.

3. Compact Design: BMW oil coolers have a compact design that takes up minimal space in the engine compartment. This allows for optimized vehicle design and engineering.

4. Corrosion Resistance: BMW oil coolers are produced using materials and coatings that provide high resistance to corrosion. This extends the lifespan of the oil cooler and maintains its performance.

5. Easy Maintenance and Replacement: BMW oil coolers are designed to facilitate maintenance and replacement processes. Access points and modular structures allow for quick and easy replacement of the oil cooler.

Historical Development

The historical development of BMW oil coolers has continuously undergone innovations and improvements with advancements in automotive engineering. Here are some key points regarding the historical development of oil coolers:

1. Early Periods (1900s): The oil coolers used in early engines were generally simple air-cooled systems. These systems were sufficient for low-performance engines but could not handle the high heat loads of modern engines.

2. Mid Period (1950s-1970s): During this period, water-cooled oil coolers and more complex heat exchanger systems were developed. These innovations improved engine performance and efficiency.

3. Modern Period (1980s-Present): Today, BMW oil coolers are produced using advanced engineering techniques and high-quality materials. Computer-aided design (CAD) and manufacturing (CAM) technologies enable more precise and efficient production of oil coolers.

4. High-Performance Applications (2000s and Beyond): In modern high-performance BMW engines, oil coolers have even more advanced features. Innovative materials and manufacturing techniques allow oil coolers to offer higher performance and durability.

Conclusion

BMW oil coolers are critical components that ensure the efficient and durable operation of the engine. Historically, oil coolers have continuously undergone innovations and improvements, ensuring that BMW engines deliver superior performance. Produced with high-quality materials and advanced manufacturing techniques, BMW oil coolers ensure the smooth and long-lasting operation of the engine. The historical development of oil coolers reflects advancements in automotive engineering, making each new generation of BMW engines more efficient and durable.

Türkçe

Türkçe

English

English

Русский

Русский