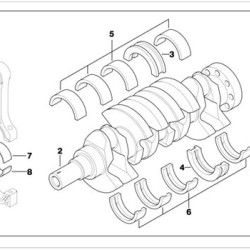

BMW Main Bearing

BMW Main Bearing is the name given to the engine parts arranged in the engine block, on which the crankshaft is placed.

Crank Main Bearings in BMW Engines: Features and Historical Development

Crank main bearings, which are one of the critical components for ensuring the high performance and durability of BMW engines, play an important role in the operation of the engine. In this article, we will examine the features and historical development of crank main bearings used in BMW engines.

Features of Crank Main Bearings

Crank main bearings are located between the crankshaft and the engine block and ensure the smooth rotation of the crankshaft. Here are some key features of BMW crank main bearings:

High Strength: Crank main bearings are made from durable materials because they operate under high pressure and load. Materials such as steel and bronze alloys are commonly used.

Low Friction Coefficient: These bearings are coated with materials that have a low friction coefficient. This reduces friction, minimizes energy loss, and increases engine efficiency.

Heat Resistance: Crank main bearings are designed to withstand the high temperatures of the engine. This prevents deformation and wear of the bearings.

Lubrication Channels: The lubrication channels on the bearings allow the flow of engine oil, reducing friction and preventing wear. These channels ensure the smooth and long-lasting operation of the bearings.

High Precision: Crank main bearings are manufactured with an accuracy of one-thousandth of a millimeter. This ensures the correct alignment and stable operation of the crankshaft.

Historical Development

BMW's crank main bearings have continuously evolved over the years with technological advancements and engineering innovations. Here are some key points regarding the historical development of these bearings:

Early Periods (1970s and Before): In the early BMW engines, crank main bearings were typically made of cast iron and bronze materials. These bearings experienced high friction and wear issues while performing their basic functions.

1980s: During this period, lighter and more durable materials such as steel and aluminum alloys began to be used. Additionally, special coatings that reduce friction were applied to the bearing surfaces.

1990s: BMW improved the performance of crank main bearings by using precision engineering and manufacturing techniques. During this period, computer-aided design and manufacturing (CAD/CAM) technologies became widespread.

2000s and Beyond: In modern BMW engines, crank main bearings are produced with advanced materials and nanotechnology. These bearings have a lower friction coefficient and higher heat resistance. Additionally, lubrication systems integrated with engine control units (ECU) ensure optimal lubrication of the bearings.

Conclusion

Crank main bearings in BMW engines are a critical component for ensuring high performance and durability of the engine. Historically, these bearings have undergone continuous innovations and improvements, ensuring that BMW engines deliver superior performance. Manufactured with high-quality materials and advanced production techniques, BMW crank main bearings ensure the smooth and long-lasting operation of the engine. The historical development of crank main bearings reflects advancements in automotive technologies, making each new generation of BMW engines more efficient and durable.

Türkçe

Türkçe

English

English

Русский

Русский