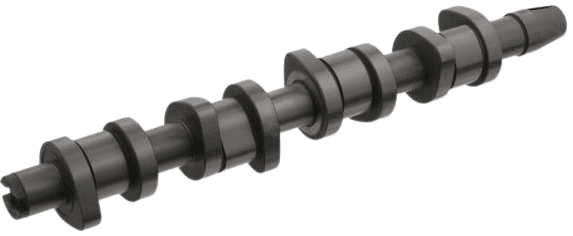

BMW Camshaft

BMW Camshaft; are parts that help to adjust the timing of the opening and closing of the valves in vehicles. These parts move in parallel with the engine's rotation and are placed on top of the vehicle's engine.

BMW Camshaft: Features and Historical Development

The camshaft is one of the critical components of internal combustion engines. It regulates the intake of air and fuel mixture into the combustion chamber and the exit of combustion products by opening and closing the engine's valves. The camshafts used in BMW vehicles are designed to provide high performance and durability. In this article, we will examine what a BMW camshaft is, its features, and its historical development.

Features of the Camshaft

BMW camshafts are specially designed and manufactured to ensure the efficient operation and longevity of the engine. Here are some key features of BMW camshafts:

1. High Strength: BMW camshafts are made from high-strength steel or forged iron. These materials are resistant to high temperatures and pressures.

2. Precision Manufacturing: BMW camshafts are produced with high precision. This ensures accurate valve timing and efficient engine operation.

3. Wear Resistance: Camshafts are equipped with wear-resistant materials and surface coatings. This ensures long-lasting use.

4. Heat Management: BMW camshafts are resistant to high temperatures, maintaining the thermal balance of the engine and optimizing its performance.

5. Performance-Enhancing Design: BMW optimizes its camshafts to enhance performance and fuel efficiency. This ensures smooth operation of the engine even at higher RPMs.

Historical Development

The historical development of BMW camshafts has continuously undergone innovations and improvements with advancements in automotive engineering. Here are some key points regarding the historical development of camshafts:

1. Early Periods (1900s): The camshafts used in early engines were generally made from simple forged iron parts. These shafts were sufficient for low RPM and low power engines.

2. Middle Period (1950s-1970s): During this period, the use of steel and other alloys became widespread. More durable and precisely manufactured camshafts improved engine performance.

3. Modern Period (1980s-Present): Today, BMW camshafts are produced using advanced engineering techniques and high-quality materials. Computer-aided design (CAD) and manufacturing (CAM) technologies allow for more precise and efficient production of camshafts.

4. High-Performance Applications (2000s and Beyond): In modern high-performance BMW engines, camshafts have even more advanced features. Innovative materials and manufacturing techniques enable camshafts to offer higher performance and durability.

Conclusion

BMW camshafts are critical components that ensure the efficient and durable operation of the engine. Historically, camshafts have continuously undergone innovations and improvements, ensuring that BMW engines deliver superior performance. Manufactured with high-quality materials and advanced production techniques, BMW camshafts ensure smooth and long-lasting engine operation. The historical development of camshafts reflects advancements in automotive engineering, making each new generation of BMW engines more efficient and durable.

Türkçe

Türkçe

English

English

Русский

Русский