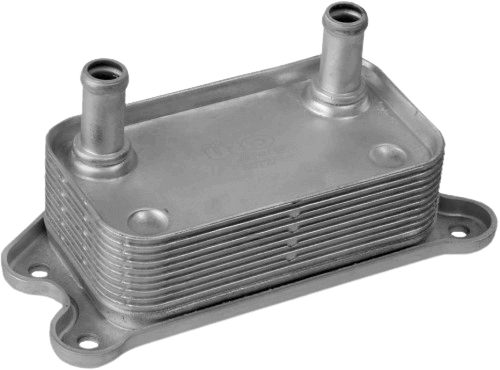

BMW Transmission Cooler

BMW Transmission Oil Coolers are small external radiators placed in front of the engine's cooling system. In some vehicles, this system is also placed under the cooling radiator and cools the high-temperature oil passing through it.

BMW Transmission Cooler: Features and Historical Development

BMW transmission cooler is an important component that prevents the vehicle's transmission system from overheating, thereby enhancing the performance and lifespan of the transmission. In this article, we will examine the features and historical development of the BMW transmission cooler.

Features of the Transmission Cooler

BMW transmission coolers are designed to provide high performance and durability. Here are some key features of these coolers:

High Heat Transfer Efficiency: BMW transmission coolers have a thin tube and fin structure that can quickly and effectively transfer the heat of the transmission oil to the external environment. This keeps the transmission oil at an ideal temperature.

Lightweight and Durable Materials: Transmission coolers are typically made from lightweight and durable materials such as aluminum. This reduces the weight of the vehicle while ensuring the cooler's longevity.

Corrosion Resistance: BMW transmission coolers are coated with materials resistant to corrosion. This increases the cooler's durability against environmental factors and ensures long-term use.

Compact Design: These coolers have a compact and efficient design that fits into the vehicle's engine compartment. This provides ease of installation and compatibility with vehicle design.

Historical Development

The historical development of BMW transmission coolers has continuously undergone innovations and improvements alongside advancements in automotive technologies:

Early Years (1970s and Before): In the early BMW vehicles, transmission coolers were made from larger and heavier materials. Cooling efficiency was limited, and coolers often required maintenance.

1980s: During this period, lighter and more efficient materials such as aluminum began to be used. The design of transmission coolers became more compact, and cooling performance improved.

1990s: BMW increased corrosion resistance in transmission coolers by using new coating technologies. Systems integrated with electronic control units began to optimize transmission performance.

2000s and Beyond: In modern BMW vehicles, transmission coolers are produced using advanced materials and manufacturing techniques. Both performance and environmental impacts have been optimized with eco-friendly coolant oils and energy-efficient designs. Additionally, thanks to electronic control systems, transmission temperature is monitored and controlled more precisely.

Conclusion

BMW transmission coolers are critical components that prevent the overheating of the transmission system and enhance its performance. Historically, these coolers have continuously undergone innovations and improvements, ensuring that BMW vehicles offer superior transmission performance. Manufactured with high-quality materials and advanced production techniques, BMW transmission coolers provide a safe and comfortable driving experience for both the driver and passengers. The historical development of transmission coolers reflects advancements in automotive technologies, making each new generation of BMW vehicles more efficient and durable.

Türkçe

Türkçe

English

English

Русский

Русский