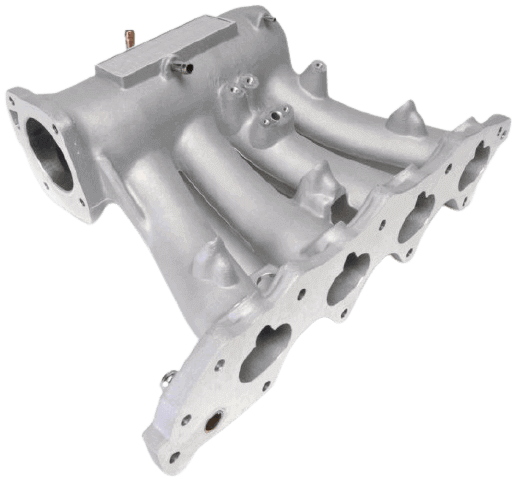

BMW Intake Manifold

The BMW intake manifold is the part that sends air coming from the air filter in vehicles to the cylinders through the intake valves, according to the engine's needs.

BMW Intake Manifold: Features and Historical Development

The BMW intake manifold is an important component designed to enhance engine performance and efficiency. The intake manifold optimizes the combustion process by distributing the air-fuel mixture evenly and efficiently to the engine's cylinders. In this article, we will examine the features and historical development of the BMW intake manifold.

Features of the Intake Manifold

BMW intake manifolds have various features specifically designed to maximize engine performance:

High Flow Efficiency: BMW intake manifolds are aerodynamically optimized to maximize airflow. This allows the engine to take in more air and improves the combustion process.

Lightweight Materials: BMW typically uses aluminum or composite materials in its intake manifolds. These materials reduce weight while increasing durability and improving overall engine performance.

Variable Intake Geometry: Modern BMW engines feature variable intake geometry technology in the intake manifold. This technology provides optimal airflow at different engine speeds, ensuring the engine performs best at every RPM.

High Precision: BMW intake manifolds are manufactured with high precision. This ensures the air-fuel mixture is evenly distributed to each cylinder, enhancing combustion efficiency.

Historical Development

BMW's intake manifolds have continuously evolved over the years with technological advancements and engineering innovations. Here are some key points in the historical development of BMW intake manifolds:

Early Period (1970s and Before): Early BMW vehicles used simple cast iron manifolds. While this manifold was low-cost and durable, it was limited in terms of airflow efficiency.

1980s: BMW began introducing aluminum alloy intake manifolds. During this period, more complex internal designs were developed to increase airflow and improve engine performance.

1990s: BMW started using variable intake geometry (VANOS) technology. This technology allowed for the adjustment of the timing and degree of the intake valves, enabling the engine to operate more efficiently at different RPMs.

2000s: BMW began using plastic and composite materials in intake manifolds. These materials significantly reduced weight while also lowering costs. Additionally, during this period, dual VANOS and Valvetronic systems were introduced, further enhancing the engine's airflow and performance.

Present Day: Modern BMW engines utilize advanced intake manifold designs and materials. These systems, combined with variable intake geometry and turbocharging technologies, provide both high performance and fuel efficiency.

Conclusion

The BMW intake manifold is a critical component that enhances engine performance and efficiency. Continuously developed over the years, this system is equipped with features such as high flow efficiency, lightweight materials, variable intake geometry, and high precision. BMW's expertise in engineering and design ensures that intake manifolds always deliver top-level performance. The historical development of the BMW intake manifold reflects advancements and innovations in automotive technologies, ensuring that each new generation of engines is more powerful and efficient.

Türkçe

Türkçe

English

English

Русский

Русский