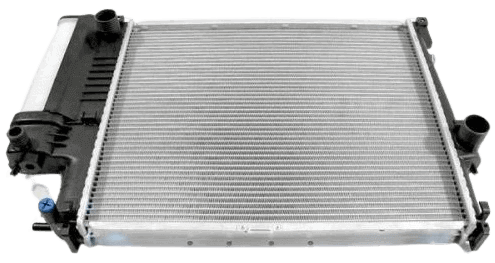

BMW Heater Radiator

The heater radiator is the part that transfers heat from the engine to the air and ensures the warming of the vehicle interior.

BMW Heater Radiator: Features and Historical Development

The BMW heater radiator is an important component used to heat the vehicle's interior cabin. This radiator, integrated into the engine cooling system, heats the air inside the cabin using the engine's temperature. In this article, we will examine the features and historical development of the BMW heater radiator.

Features of the Heater Radiator

BMW heater radiators are designed to provide high performance and long life. Here are some key features of these radiators:

High Thermal Conductivity: Heater radiators are made from materials with high thermal conductivity, such as aluminum or copper. These materials effectively transfer the heat of the engine coolant to the cabin air quickly.

Compact Design: BMW heater radiators offer compact and efficient designs to fit into the limited space inside the vehicle. This provides ease of installation and compatibility with interior arrangements.

Corrosion Resistance: Heater radiators are coated with corrosion-resistant materials to ensure long life and durability. This prevents rust and leakage in the radiator.

Effective Heat Distribution: BMW radiators are designed to distribute heat evenly and quickly. This ensures that the cabin warms up quickly and evenly.

Historical Development

The historical development of BMW heater radiators has continuously undergone innovations and improvements alongside advancements in automotive technologies:

Early Periods (1970s and Before): In the early BMW vehicles, heater radiators were generally simple and large. These radiators were made from heavy materials like iron or copper, resulting in low heating efficiency.

1980s: During this period, lighter materials with higher thermal conductivity, such as aluminum, began to be used. The design of heater radiators became more compact, and heating efficiency was improved.

1990s: BMW introduced new coating technologies to enhance corrosion resistance and extend radiator life. Additionally, electronic control systems integrated with engine control units allowed for more precise adjustment of cabin temperature.

2000s and Beyond: In modern BMW vehicles, heater radiators are produced using advanced materials and manufacturing techniques. With environmentally friendly coolants and energy-efficient designs, both performance and environmental impacts have been optimized. Thanks to electronic control systems, cabin temperature and airflow can be adjusted more precisely.

Conclusion

BMW heater radiators are important components designed to provide high performance, durability, and efficiency. Historically, these radiators have continuously undergone innovations and improvements, ensuring that BMW vehicles offer superior heating performance. Manufactured with high-quality materials and advanced production techniques, BMW heater radiators provide a comfortable driving experience for both the driver and passengers. The historical development of heater radiators reflects advancements in automotive technologies, making each new generation of BMW vehicles more efficient and durable.

Türkçe

Türkçe

English

English

Русский

Русский